Seward’s Garage, Southampton

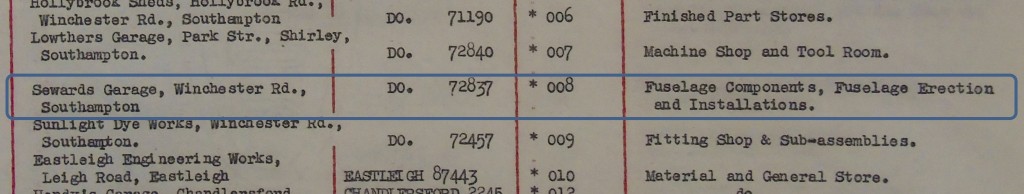

Southampton Area dispersal workshop.

One of two workshops already requisitioned and under preparation prior to the raids on the Woolston and Itchen Works on 24th and 26th September 1940.

Following the bombing of Woolston it was pressed into service to keep production running whilst the other workshops were requisitioned and set-up. Once established, the two-floors of the garage and showroom were use for the production of Jigs and Spitfire fuselages; from individual components to finished fuselage assembly.

The Garage remained in use and remained in use by Supermarine until the end of the war in Japan.

Overview

Role of Seward’s Garage in Spitfire Production

Places

Location of Seward’s Garage in Southampton

People

List of known Supermarine workers in Seward’s Garage

Overview

Preparation

September 1940

Seward’s Garage was the second of two workshops that were already in the process of being prepared for Spitfire work before the first concerted attempt to bomb the Works on 15th September 1940. The vulnerability of the large, and highly visible, main Works factories to enemy attack had long been understood by Supermarine’s management, however, the pressure to maintain production levels had largely put any plans to disperse production on hold.

The plans that had been made had been largely focused not on the replacement of production at Woolston and Itchen but on the provision of additional capacity by moving some of the spare jigs into the new workshops, as much to free space in Woolston and Itchen as to increase production. A similar process having already been applied to the Coppersmith’s with their move to the Weston Rolling Mills in March 1940.

By early September Hendy’s Garage, on Vincent’s Walk in the centre of Southampton, and Seward’s Garage on Winchester Road in Upper Shirley had been identified, requisitioned and Supermarine workmen had begun to setup the workshops.

At Seward’s Garage the work was managed and overseen by one of the Itchen Works fuselage production-line foremen Gilbert Olsen.

Olsen had been a member of the Works Engineer’s Office and had also worked in the Jig & Tool Design team before moving to work on Spitfire fuselages in the Itchen Works. So he was well qualified to ensure the Spitfire fuselage jigs were correctly setup at Seward’s.

As a motor vehicle garage Seward’s was a perfect choice for fuselage assembly. Like Hendy’s, and in what would become a fairly standard pattern in the following weeks, Seward’s possessed the required space and facilities. Requirements Cyril Russel was to describe in his account of his time at Supermarine:

“It was quickly realised that premises with good concrete floors and large uncluttered areas free from stanchions and pillar supports for reasonably higher than average ceiling clearance, plus fair size access doors, were required and, in this category, immediately obvious and available, were car showrooms and garages.”

Russell, Cyril, Spitfire Odyssey, p91 (1990)

Air Raids

(15th – 26th September 1940)

The pressure to complete the setup at both Seward’s and Hendy’s increased after the 15th September when the Luftwaffe mounted their first targeted attack on Supermarine’s main factories.

Up until September the Supermarine factories had led a charmed life but the successes of the RAF in the air were to lead to a change in the Luftwaffe’s tactics, as they began to target the aircraft manufacturing facilities across the country.

The raid itself was, for Supermarine, largely ineffectual. Little damage was done to the Works and no casualties were recorded at the factories. However, the raid did cause substantial damage and loss of life in the immediate vicinity of the Works, as the bombs missed their intended target and struck nearby residential areas. It also pressed home the urgent need for Supermarine to disperse at least some production capacity before it was destroyed. Supermarine immediately began the process of requisitioning additional premises including the Hants & Dorset Bus Garage, Sunlight Sye Works & Laundry and the Hollybrook Sheds, all in close proximity to Seward’s.

In the following days preparations at Seward’s continued, under the direction of Olsen. Then, on Tuesday 24th September, Olsen had to return to the Itchen Works for some papers just as the Luftwaffe mounted a major raid on the factory.

My uncle Gilbert also worked in the Drawing Office, [he] was at home needed some paper work. [He] went back and got caught.

Interview with Peter Lucas, nephew of Gilbert Olsen

In a cruel irony, the man charged with setting up Spitfire production in new ‘safer’ workshops away from the main Works was one of twenty-nine Supermarine workers known to have been killed in the bombing.

For the workers involved in setting up the garage the smoke from the raid could be seen from the roof of Seward’s Garage and two days later the Luftwaffe returned and finished the job they had started, By the end of Thursday 26th September 1940 the future of both the Woolston and Itchen Works had been sealed and Seward’s was no longer a useful expansion but a key part of a rapidly evolving plan to completely disperse production.

Early Dispersal

(26th September – November 1940)

Whatever the initial plans had been for Seward’s the bombing changed them. One of the first priorities for Supermarine was to get some form of production back-up and running. Inside Woolston a limited production line was back in operation even as the debris of the bombing was being cleared, some of it working under makeshift tarpaulin ‘roofing’. At the same time the new workshops identified after the 15th were rapidly pressed into use and more location earmarked as Supermarine moved towards a full dispersal of production as the Jigs and machine tools were quickly moved out of the ruined Works.

However, it would be a mistake to view this early dispersal as planned or organised. It was by it’s very nature a reaction to a disaster where speed was of the essence. It was clear that the strategy was ‘get it done and worry about it later’ and Seward’s was no different as Cyril Russell was to recall, it had been used as a dumping ground as the other locations were identified, requisitioned, cleared and prepared. In the meantime Hendy’s and Seward’s bore the brunt of what dispersed work could be performed.

Within a week of the bombing, Cyril Russell was moved to Seward’s to continue his wheeling (Sheet metal working / panel beating on the ‘English Wheel’, a large machine tool for shaping the sheets of aluminium alloy that formed the ‘skin’ of the Spitfire)

The speed of events are reflected in my own moves. Tuesday and Wednesday I worked on fuselages in Hendy’s Garage, and on Thursday I was sent to Seward’s Motors which, apart from being used as a dumping and sorting ground, provided just enough room in the front part of its upper floor for the wheeling squad to be reconstituted after we had sorted out our wheeling machines, jigs and materials. It was all rather like Fred Karno’s Army as some jigs were still missing, as well as certain material gauges being unavailable.”

Russell, Cyril, Spitfire Odyssey, (1985) p.91

Note: Fred Karno’s Army was an expression used to describe any chaotic or disorganised group

However, on 22nd October 1940 Cyril and his fellow Wheelers were moved to the requisitioned (but not yet cleared) Hendy’s Agricultural Showroom in Chandlers Ford and it seems reasonable to conclude that by November, with many of the Southampton workshops now under Supermarine control, Seward’s could begin to function properly as a part of that dispersed production.

Dispersal Production

(November 1940 – 1946)

Sources

Precisely how Seward’s fit into the overall Spitfire production process, and where it sat in the newly created ‘Southampton Area’ is detailed in the List of Vickers Premises as of 1st January 1944. This list of all of the premises in use by Vickers (not just Supermarine) is a specific snapshot but does give a good overall picture of the work being done. This picture of Spitfire production is enhanced by several commemorative photographic albums compiled by Supermarine to record and commemorate the dispersal and work done in each location.

However, both the List of Premises (Vickers Archive Ref. 723) and Commemorative photograph albums only give limited snapshots of the work done and Cyril Russell’s account, and those of other workers, indicate that the picture presented is a good, but simplified, picture.

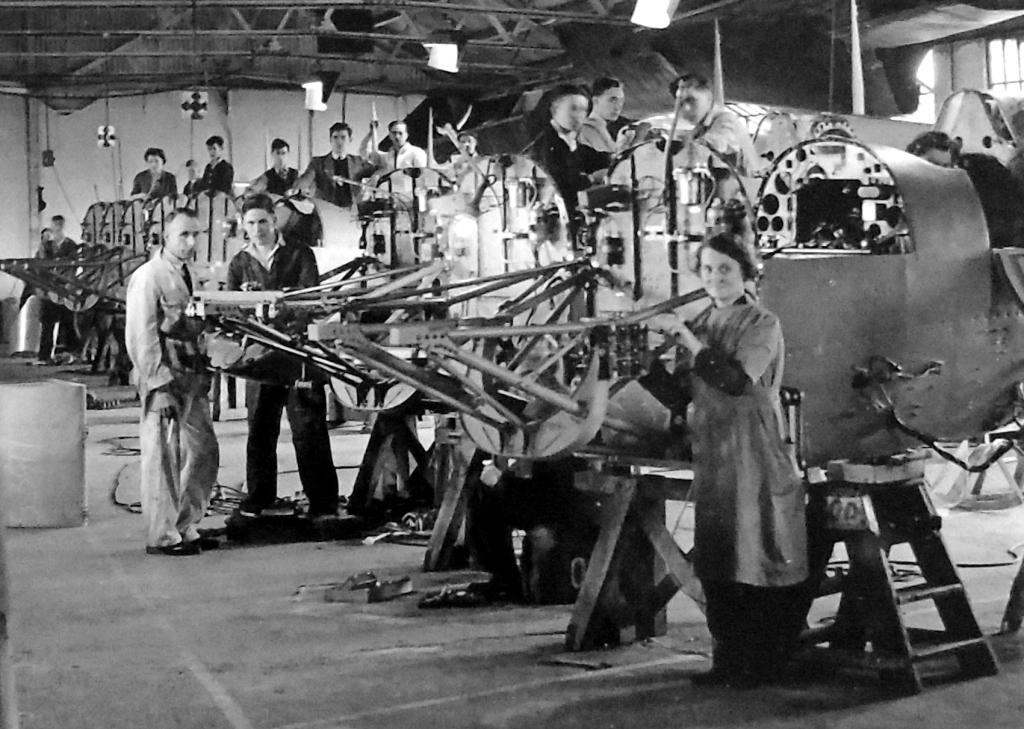

What seems clear is that at Seward’s there was a clear division of work between the Upper and Lower floors of the garage. Each floor taking on a different part of the production process before handing on to the next stage. The following assessment of Seward’s Garage is based upon the combination of the listed sources and the commemorative photographs (which probably date to c.1943)

Upper (Top) Floor

(Jig Construction and Fuselage Assembly)

Based on the images of the top floor of Seward’s garage shown in the commemorative Dispersal Unit photographic albums, the floor was used for the first part of Stage 2 Assembly. Spitfire fuselages are lined up, out of their jigs (stage 1 fuselage assembly using jigs was performed at Hendy’s Garage on Vincent’s Walk) and are in the process of having the internal equipment, including oil tanks seen in the image, fitted.

In addition to the actual manufacture of fuselages the top floor of Seward’s also appears to have had a part of the floor assigned to the manufacture of the Jigs required for the manufacture of everything from small sub-assemblies to the large fuselage and wing jigs.

Lower (Bottom) Floor

(Fuselage Components and Assembly)

The ground floor of Seward’s was divided into a section for the production of Spitfire fuselage components and a section for fuselage Stage 2 assembly (the final stage before delivery to the Final Assembly workshops like Eastleigh.

The Dispersal Unit photographic albums show the fuselages slightly further down the production line than those seen on the top floor. The fuselages now have the cockpit canopy and windscreen fitted as well as the engine.

Post war

Release of premises

As the end of the Second World War drew closer plans as to what to do with the requisitioned sites began to be discussed by Supermarine and in May 1945 a memo detailed the proposed sequence of disposal of requisitioned properties. The process was to begin in June 1945 with the release of the Fore Street Garage in Trowbridge followed by a dozen other locations by the end of 1945. Seward’s was planned to remain in use until the end of the War with Japan or in June 1946 “if the Japanese War finishes before that date”.

In the end the war in Japan ended on 15th August 1945 but it is not yet clear exactly whether the location was returned to Seward Motors or whether the lease was taken up by Folland Aircraft without a gap.

Folland AircrafT

(c.1946-1950s)

In the post war period Folland Aircraft took over use of, at least, the lower floor of Seward’s as part of their production base for aircraft. It is possible that this was done directly from Supermarine in 1946, however, at this time Folland Aircraft was suffering from a lack of work rather than capacity and it may not have been until c.1948 that there was a requirement for additional production capacity with the signing of a contract with De Havilland to produce aircraft wings for them.

A photograph, date 1952, in D. James’s “Spirit of Hamble Folland Aircraft” shows a Folland Aircraft Ltd. lorry leaving Seward’s garage laden with wings for a De Havilland Venom.

By the 1954 it is probable that Seward’s was being used by Follands to make wings for their own aircraft, the Folland Gnat. However, by 1959 Folland Aircraft had been brought into the Hawker Siddley Group (losing the name Folland Aircraft by 1963) and it is probably to this time period that the garage stopped being a location for aircraft manufacture.

Recent history

(1960s)

By the 1960s the upper floor was being used by the Southern Gas Board for offices.

(1980s)

The original building was demolished (probably in the mid 1980s) to make way for the new retail outlet that is still on site today. The image shows the site in the process of demolition with the ramp to the upper floor already removed.

(Present Day)

Today, the site of 230-234 Winchester Road, Southampton is home to the retailer The Range.

Spitfire Makers Charitable Trust

(Blue Plaque)

On 26th June 2022 The Spitfire Makers Charitable Trust unveiled a blue plaque to commemorate the use of Seward’s Garage as a Spitfire workshop during WWII.

Placed on the wall of the adjacent Christopher Carter Veterinary Surgery, the plaque is part of “The Spitfire Makers Charitable Trust” mission to commemorate all the locations involved in Spitfire Production.

Location

Seward Motors

In 1939 Kelly’s Directory lists the Motor Car Agent, Roland Frederick Seward operating from 230 Winchester Road, Upper Shirley. The 1939 Register shows Roland’s employment as “Garage Proprietor & Government Contracts” and living at 230 Winchester Road with his family, including his father William Frederick Seward as Garage Assistant. The reference to “Government Contracts” is interesting and may possibly hint as to why Seward’s was identified so early as a possible dispersal workshop.

The 1939 Register also confirms that the Garage extended from 230 to 234 Winchester Road, Upper Shirley in Southampton. This area of Shirley included a few additional industrial units that were to prove useful to Supermarine. Almost opposite to Seward’s were the Sunlight Dye Works and Laundry and the Hants & Dorset Bus Company garage. Both of these premises being requisitioned shortly after the 26th September. The Sunlight Dye Works & Laundry was used as a Fitting Shop and made sub-assemblies, while the Hants & Dorset Bus Company garage (with it’s high roof for double-decker buses) proved ideal for Wing Assembly. Together these three workshops, combined with the new Finished Parts Store in the “Hollybrook Sheds”, formed an effective Spitfire production hub.

Personnel

Foreman

Crooks, Bill

pre. 1935- 1944+

Foreman in “E” Shop (Erecting Shop) at Woolston in 1935 and continued in role until bombing on 26th September. Following the raid appears to have been made foreman at Seward’s Garage where he is listed foreman in 1944.

When Dudley Morris joined as a “Handy Lad” straight from school, he recalled Bill as “that wonderful gravel voiced character Bill Crooks who was not nearly as fierce as his shaggy eyebrows and bifurcated vision made him appear!”.

Workers

Pre-Dispersal & Post-Bombing

(September 1940 – October 1940)

Olsen, John Gilbert

pre-1939 – 24th Sept 1940

Jig & Tool then Foreman of Spitfire Production line at Itchen Works. Working for Works Management organising setup of Seward’s Garage in Septemeber 1940 but killed in Air Raid while returning to Itchen Works on 24th September 1940

Russell, Cyril

1937 – 24th Sept 1940

Sheet Metal Worker (Wheeler) in ‘K’ Shop at Woolston. Temporarily moved to Seward’s Garage September 1940 after bombing until moved to Hendy’s Agricultural Showroom in Chandlers Ford on 22nd October 1940

Dispersal

(October 1940 – August 1945)

Lee, Florence “Flossie”

1941-1944

Started working at Seward’s Garage, probably in early 1942 aged 20, where she was involved in fuselage assembly, in particular the wiring in the tail section where the cramped space made her small statute an advantage. Continued to work there until her marriage in 1944.

Williamson, Frank

c.1941-1944

At the outbreak of war in 1939 Frank was working in Southampton Docks as a *ship’s tank cleaner labourer*, cleaning the funnels of the many ships then using the port. It is not clear when he joined Supermarine but it would probably have been around 1940-1941 when German attacks on shipping in the channel, combined with the bombing of the docks, caused a reduction in dock work. As dock work declined so the number pf jobs on the expanding dispersed Spitfire workshops increased. This combination made a change in employment likely, indeed it was being actively encouraged by the government at the time.

Frank continued to work at Seward’s until his death in 1944, whilst making his way to work on the bus from his home in Sholing.

Unknown

c.1942-1945

My mother, along with a number of other mothers of young children, (mothers with only older children had to work in factories, shops etc.) were asked to take paying guests into their homes. My mother had two young girls from 17-18 years old upwards, for four weeks at a time, who lived with the family and were provided with full board and keep for a certain payment per week, to cover the cost of their care. These girls were trained in engineering skills and then sent off to work in factories around the country. One of the girls was sent to Seward’s Garage in Winchester Road, to work on the making of parts towards the assembly of the Spitfire – work which was contracted around many sites throughout Southampton after the Supermarine Works was bombed.”

Mother’s War Effort: Your Stories Friends of St James’ Park

Thanks for a very interesting and comprehensive piece about Seward’s.

Roland Seward was my uncle, although I never knew him.

I didn’t know that he was already a Govt Contractor in 1939. I was told many years ago that he had set up an engineering business – Lingwood Precision – which made components for landing gears, based in the former stables of his house, Lingwood, in the Avenue – now I think replaced by housing. If the Winchester Rd building was taken over in its entirety in 1940, that might explain why it ended up in Lingwood.

A tiny correction, if I may – the original building was replaced in about 1958 by a new showroom building – the link below describes it. Unfortunately the images don’t seem to be available here, but they are in the Echo’s archives. As you mention, the showrooms must have been themselves replaced in the 1980’s.

http://www.sopse.org.uk/ixbin/hixclient.exe?a=query&f=generic_searchresults.htm&p=gateway&m=quick_sform&text=seward&b.x=14&b.y=7&tc1=b

LikeLiked by 1 person

Hi Bill,

Many thanks for your comments and for the “tiny correction”. All corrections are welcome, it’s how we learn and what will help improve the site.

If you find any more on your uncle or the links with Supermarine that you can share do let me know.

All the best

Dave

LikeLike